Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Animal Feed & Nutrition Functions

- Ingredients

- Dextrose, Lactobacillus Plantarums, 8-Hydroxynoline, Pediococcus pentosaceus, Propionibacterium freudenreichii

- Technologies

- Product Families

- Compound

Bacteria:

- Lactobacillus buchneri,

- Lactobacillus plantarum,

- Propionibacterium freudenreichii

- Pediococcus pentosaceus.

Features & Benefits

- Animal Feed & Nutrition Features

- Benefits

- Quickly lowers the pH of the feed to the optimum level;

- Ensures the safety and aerobic stability of the feed, preventing the development of mold and yeast;

- Increases the digestibility of fiber and feed intake;

- Reduces the loss of nutrients;

- Reduces dry matter loss.

- Biological Properties

- LactoGras FS® contains strains of homofermentative and heterofermentative lactic acid bacteria of a new generation.

- Pediococcus pentosaceus provides a rapid pH reduction under aerobic conditions during the initial ensiling phase.

- Lactobacillus plantarum provides an optimal concentration of lactic acid under anaerobic conditions and high acidity.

- Lactobacillus buchneri is a heterofermentative bacterium that produces acetic acid, which ensures the stability of succulent feed after opening the trench and on the feed table.

- Propionibacterium freudenreichii process excess lactic acid into propionic acid, which inhibits the growth and development of mold, clostridium and yeast, is a fatty acid producer that provides high palatability and nutritional value of silage or haylage.

- Each of the strains controls and improves the overall fermentation. In laboratory and production tests, reliable results have been obtained confirming the effectiveness of the preservative in inhibiting the growth of various bacteria, yeasts and molds leading to feed spoilage.

Applications & Uses

- Markets

- Applications

- Animal Species

- Application

- The product is used in the form of a solution at the rate of 1 g of preservative per 1 ton of fresh weight of fodder.

- To prepare the mother liquor, the required amount of biological preservative is dissolved in 5-10 liters of pure dechlorinated water. To obtain a working solution, the mother liquor is introduced into the working container and pure dechlorinated water is added.

- The solution is sprayed evenly on the forage mass when cutting or when entering into a silo pit using a dosing pump.

- For spraying, all types of agricultural metering pumps are used, well cleaned of chemical residues. The solution must be used within 48 hours. The application rate is determined taking into account the performance of the dosing pump and the concentration of the working solution.

The application rates of the biopreservative "LaktoGras FS" when harvesting fodder mass:

The amount of mother liquor per 100 tons of forage mass The amount of water for preparing a working solution per 100 tons of forage mass Volume of working solution for application per 100 tons of forage mass Productivity of the dosing pump (rate of application of the working solution) per 1 ton of green mass

5 l 195 l 200 l 2 l/t 5 l 395 l 400 l 4 l/t

Properties

- Typical Properties

Value Units Test Method / Conditions Bacteria 1x10¹¹ CFU/g - Filler Dextrose - -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Grass Senage

Comprehensive assessment of haylage quality according to GOST 23637-90 (n=50)

A sample Bulk

Share

dry

substances

%Mass fraction

in dry matterBulk

Share

oily

acid,

%pH "Nutrition 1 kg

dry matter"Raw

protein

%Raw

fiber,

%Exchange

energy,

MJ/kgfodder

unitsLactograss FS® 51.3±1.8 19.6±2.1 25.2±1.7 0 4.7±0.1 10.54±0.3 0.89±0.2 CONTROL 52.0±2.7 14.2±2.9 32.8±2.2 0.1±0.07 5.7±0.3 9.22±0.4 0.67±0.3 Ratio exchange energy in haylage Ratio feed units in haylage

The use of the preservative LactoGras FS® when laying haylage leads to an increase in the number of lactic acid bacteria. In the process of their vital activity, there is a rapid increase in the concentration of lactic acid, which entails a decrease in pH to an optimal level.

When laying haylage without a preservative, active growth of microorganisms is observed: Clostridium spp, yeast, etc., which causes protein breakdown with the formation of toxic biogenic amines. Mold growth leads to the accumulation of mycotoxins in the silage.

- Corn Silos

Comprehensive assessment of the quality of corn silage according to STB 1223-2000 (n=50)

A sample Bulk

share

dry

substances

%Mass fraction in dry matter

pH Content oily

acid, 9%Nutrition 1 kg

dry matterRaw protein % Raw fiber% Raw ash % Exchange

energy,

MJ/kgFodder

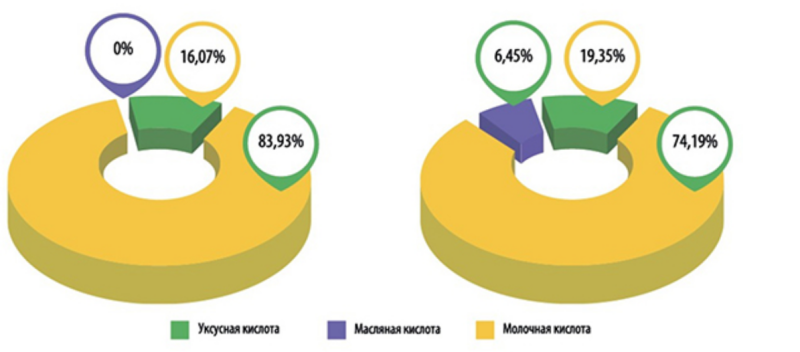

unitsLactograss FS® 28.1±1.6 12.0±1.9 20.3±2.1 5.9±1.4 4.0±0.1 0 10.04±0.1 0.9±0.2 CONTROL 25.7±2.7 8.9±2.4 24.8± 2.3 7.6±1.8 4.2±0.3 0.1±0.04 9.59±0.3 0.86±0.2 The ratio of organic acids in the silage when using Lactogras FS® & The ratio of organic acids in the silage no preservative

Silage preservation processes can proceed according to the type of controlled and uncontrolled fermentation. When implementing controlled fermentation using LactoGras FS, there is a rapid decrease in pH to 5.0 by the second day, and after 4 days the pH reaches 4.2 units. The creation of anaerobic conditions leads to a halt in the growth and reproduction of undesirable microflora: enterobacteria, yeast, mold fungi. The silage matures by 21 days from the date of laying.

The process of uncontrolled fermentation without the use of a preservative leads to spoilage of the silage mass. The decrease in temperature and pH is much slower. Aerobic microorganisms lead to the breakdown of nutrients and the formation of butyric acid, self-heating of the silage mass.

Packaging & Availability

- Packaging Type

- Package

Packed in bags of polypropylene metallized film with a net weight of 500g.

Storage & Handling

- Storage and Shelf Life

- Store in dry, clean, well-ventilated warehouses at temperatures from -18°С to +4°С and relative humidity not higher than 85%.

- Shelf life in original undamaged packaging is 24 months from the date of manufacture.