Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Additives Included

- Chemical Family

- Core Type

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Weight 1.2 mg - Size 2.5 – 4.5 mm - Bulk Density 28-32 g/l -

Regulatory & Compliance

- Certifications & Compliance

- Food Approved

Yes

Technical Details & Test Data

- Physical Properties

Test method 40g/l 55g/l Compressive strength

25% strain (kPa)

50% strain (kPa)

75% strain (kPa)ISO 844

5 mm/min210

300

600310

420

900Tensile strength (kPa)

Tensile elongation (%)ISO 1798 640

28860

26Compression set

25% strain – 22 hours – 23°C (%)ISO 1856 (Method C)

Stabilizing 24h11.5 11.5 Burn rate (mm/min) ISO 3795

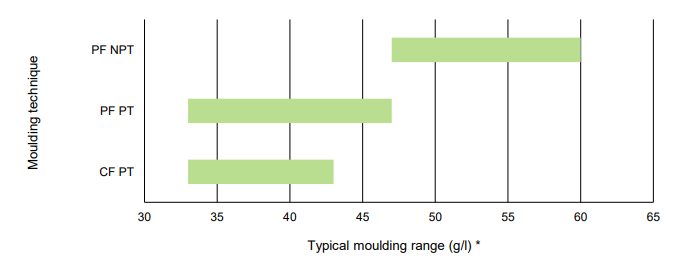

12.5mm thick60 45 - Moulding

ARPRO 5130 can be molded using Crack Fill (CF) and Pressure Fill (PF):

Crack fill: preferably applied to Pre-Treated (PT) ARPRO.

Pressure fill: applied to either Pre-Treated (PT) or Non-Pre-Treated (NPT) ARPRO.

- Pre-treatment

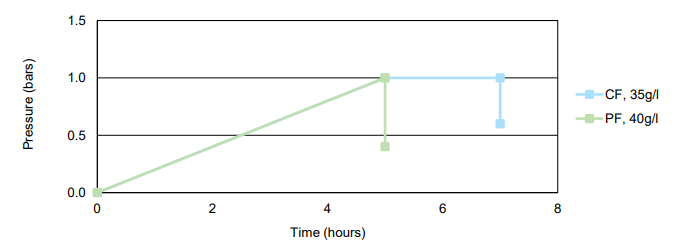

Recommended pre-treatment cycle with pressure tank environment and incoming compressed air both at 23°C:

Crack fill: 5 hours up to 1 bar, hold for 2 hours at 1 bar, decrease and maintain at 0.6 bar throughout production.

Pressure fill: 5 hours up to 1 bar, decrease and maintain at 0.4 bar throughout production.

Pre-treatment cycles can be adapted according to molding process, density and part geometry:

If internal cell pressure is too high, this may lead to fusion issues. In this case, decrease time, pressure or temperature to improve fusion.

Increase time, pressure or temperature to reduce molded density and improve aspect.

Operating the pressure tank above ambient temperature, up to a maximum of 50°C, significantly shortens pre-treatment time.- Post-treatment

For molded densities below 50g/l and depending on the parts dimensions, post-treatment at a temperature of 80°C is recommended for 3 to 8 hours. This helps to remove water content, as well as ensuring dimensional stability and a geometric shape.

- Shrinkage

Typical values range from 1.8% to 2.2%. The higher the molded density, typically the lower the shrinkage.

Packaging & Availability

- Packaging Type

- Packaging

Bulk/Bag

Storage & Handling

- Storage

A storage temperature above 15°C is strongly recommended.

Indoor storage strongly recommended.

If stored outdoors, it is strongly recommended to keep the material indoors for 24 hours before molding.