Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- Chemical Family

- Chemical Name

- Base Chemicals Functions

- Cleaning Ingredients Functions

- Technologies

- Product Families

- Material Composition

Trans-1,2-dichloroethylene: 46-54%

1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether: 43-52%

Features & Benefits

- Benefit Claims

- Labeling Claims

- Base Chemicals Features

- HII Features

- Benefits

- Non-flammable

- Non-corrosive

- Superior drying property

- Excellent permeability

- Recyclable

- Low global warming potential (GWP)

- Zero ozone depletion potential (ODP)

- No surfactants necessary

- Recoverable by simple distillation

- Can be used with ultrasonics

- Material compatibility with a wide variety of metals, plastics, and elastomers

- Excellent thermal, chemical, and hydrolytic stability

- Low surface tension, low viscosity, high liquid density

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Base Chemicals End Uses

- Home Care Applications

- I&I Cleaning Applications

- Applications

- Defluxing of printed wiring assemblies

- Precision cleaning of plastics, substrates, electrical components, metals, and particle removal

- Drying agent after cleaning with hydrocarbons or alcohols

- Replacement for HCFC, perchloroethylene, trichloroethylene, Dupont™ Vertrel®, & 3M™ Novec™ solvents

- Cleaning Procedures

It is recommended that Asahiklin AE3000AT be used in a vapor degreaser to optimize cleaning efficiency, economy, and emission control. Cleaning procedures for Asahiklin AE3000AT are quite similar to those of AK225 products. The procedures consist of immersing a workload into the boiling solvent, rinsing or spraying with cool solvent and drying in solvent vapor.

Properties

- Physical Form

- Physical Properties

Value Units Test Method / Conditions Boiling Point 38 (100.4) ºC(ºF) - Density (at 25ºC) 1.36 g/cm³ - Flash Point None - Open/Closed Cup KB Value 32 - - Latent Heat of Vaporization (at 39ºC) 185 KJ/kg - Melting Point -49.3 ºC - Relative Evaporation Rate (Ether=100) 93 - - Specific Heat (at 25ºC) 1.3 kJ/kg K - Surface Tension (at 25ºC) 18 dyne/cm - Viscosity (at 25ºC) 0.33 cSt - - Material Compatibility

Asahiklin AE3000AT has a broad range of compatibilities.

Effect of Asahiklin AE3000AT on Unstressed Plastics at the Boiling Point.At boiling for 5min At boiling for 3 days Weight

change (%)Linear Swell

(%)Extractables

(%)Weight

change (%)Linear Swell

(%)Extractables

(%)Polyvinyl chloride (rigid) 3.2 2.2 <0.1 40.9 41.3 0.7 Polyvinyl chloride (plasticized) 23.0 17.4 5.8 -9.2 -20.4 19.2 Polyethylene (HP) 8.1 5.7 <0.1 128.6 affected 1.3 Polyethylene (LP) 1.4 0.1 <0.1 23.6 18.7 4.1 Polypropylene 1.95 1.3 <0.1 38.6 27.8 1.5 Polystyrene 34.0 19.9 0.3 affected affected 103.8 Polycarbonate 16.4 19.7 <0.1 33.2 56.6 1.1 Polyacetal 0.28 0.36 <0.1 11.0 16.4 0.4 Polyphenylene oxide 30.5 22.7 0.92 affected affected 102.6 Phenolic 0.17 0.13 <0.1 9.8 9.0 0.8 ABS 38.4 24.3 0.44 154.7 affected 3.0 Nylon6 <0.1 -3.4 <0.1 5.5 2.7 <0.1 Nylon66 <0.1 0.42 <0.1 4.8 5.2 <0.1 Polyester (FR) 2.4 3.4 <0.1 18.9 26.3 3.9 PTFE <0.1 0.25 <0.1 2.7 2.6 <0.1 PCTFE 0.22 0.7 <0.1 11.3 17.4 <0.1 Epoxy (FR) 0.3 0.1 <0.1 6.8 9.9 <0.1 Polyphenylene sulfide 0.25 <0.1 <0.1 3.8 4.5 <0.1 Polybutylene terephthalate 0.82 0.18 <0.1 13.4 11.7 0.8 Polyethylene terephthalate 19.6 18.8 <0.1 64.5 72.7 1.9 Note: negative numbers denote shrinkage

Effect of Asahiklin AE3000AT on Elastomers at the Boiling Point.

At boiling for 5min At boiling for 3 days Weight change (%) Linear Swell

(%)Extractables

(%)Weight

change (%)Linear Swell

(%)Extractables

(%)Polysulfide rubber FA(T) 18.9 16.8 <0.1 61.0 52.8 11.7 Natural rubber (NR) 19.9 19.1 0.2 45.5 32.6 10.7 Urethane rubber (UR) 30.6 25.9 <0.1 138.9 109.2 4.0 Isobutylene isoprene rubber (IIR) 19.5 13.0 0.9 38.7 30.0 13.6 Polychloroprene (CR) 18.0 16.5 1.3 29.6 23.2 17.9 Fluoroelastomer E (FKM) 8.0 9.3 <0.1 82.0 103.5 3.9 Chlorosulfonated polyethylene

(CSM)15.3 14.1 1.2 29.7 23.9 10.7 Silicone rubber (Q) 63.4 44.8 <0.1 155.6 120.1 2.4 Nitryl rubber (NBR) 22.4 20.1 1.4 54.2 48.4 13 Ethylene propylene diene

terpolymer (EPDM)17.3 14.1 3.5 17.5 8.3 17.3 Effect of Asahiklin AE3000AT on Viton and PTFE at the Boiling Point.

At boiling for 7 days Weight

change (%)Linear Swell

(%)Extractables

(%)Viton (FDA White) 55.2 37.3 0.5 Viton (Chemical Resistant) 92.7 74.3 1.4 Vition (Low Temp) 72.0 56.6 0.2 Viton 73.6 57.5 7.0 PTFE 2.8 0.9 <0.1 - Environmental Properties

Properties Asahiklin AE3000AT Ozone Depletion Potential (ODP)1 None Global Warming Potential (GWP)2 *268 Flash Point None 1 CFC-11 = 1.0

2 CO2 = 1.0, 100yr ITH

* Calculated value by the AIST

Technical Details & Test Data

- Comparison

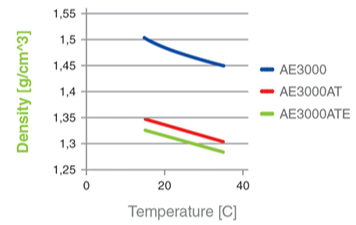

Density vs. Temperature

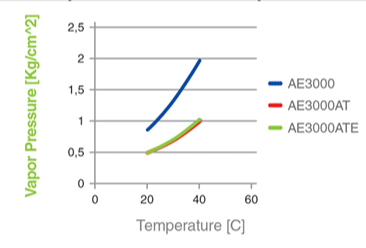

Vapor Pressure vs. Temperature

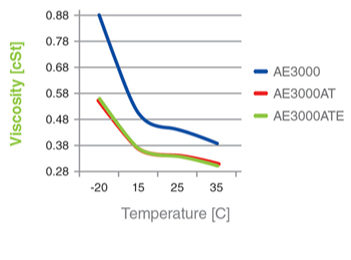

Viscosity vs. Temperature