Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Utilization

- Addibatch® MB-MBD 40227 is used by the film extrusion process (extrusion film cast & blow molding extrusion) in order to lower die build up and therefore optimize the production times. It allows improving the surface appearance and reducing the «orange peel» character. MB level recommended is 2%, but the exact concentration depends on the machine & on polymer. The existence of antiblock,& pigment in the polymer makes it more abrasive and requires therefore a higher quantity of MB. MBD 40227 is mainly used in PE, EVA or PP. It can be processed with temperatures up to 280°C, which allows the use in matrix like PS.

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Apparent Density approx. 0.50 g/cm3 ISO 60 - Thermal Properties

Value Units Test Method / Conditions Volatile Material Contents max. 0.15 % intern

Regulatory & Compliance

- Food Contact

- In specific situations MBD 40227 can be used for applications with food contact. For any information regarding the regulatory compliances, please contact QHSE department.

Technical Details & Test Data

- Note

- The fluidity (ref. to ISO 1133) can be adapted on request, according to the application

- Compounds & Masterbatches

For High Performance Plastic

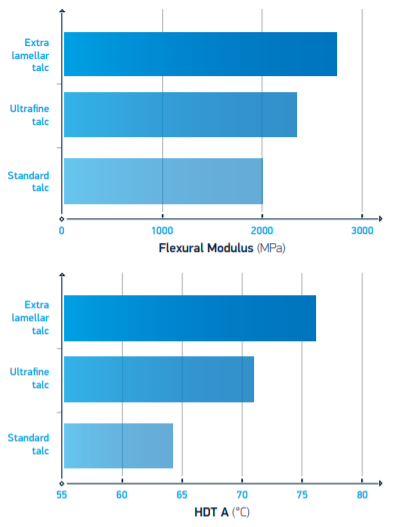

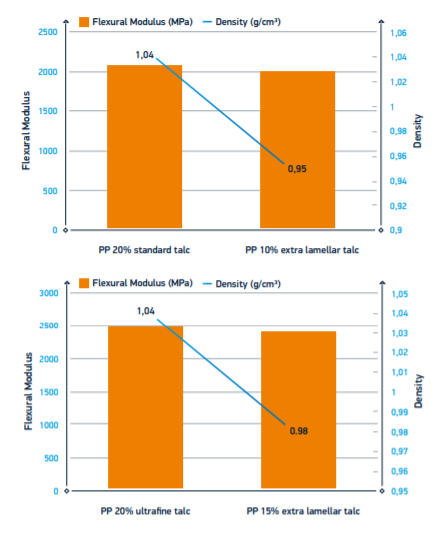

YOU WANT TO IMPROVE RIGIDITY AND HEAT DEFLECTION TEMPERATURE YOU WANT TO REDUCE WEIGHT ?

20% Talc PP compounds

Our innovative Extra lamellar Talc PP Compounds in comparison with standard and ultrafine talc.

Packaging & Availability

- Packaging Type

- Packaging

- This masterbatch is packed in PE bag

Storage & Handling

- Storage

- This must be stored protected from light and from humidity.