Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Use

- The MBD 40170 is used to reduce the electrical resistivity of the surface of films or molded parts in PE and PP. It allows to obtain a long-term antistatic effect. This masterbatch also gives lubricating effect during the molding or during the extrusion.

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Bulk Density 0.58 g/cm3 ISO 60 Moisture Content max. 0.15 % intern - Thickness of the Films on the Resin Use

The recommended incorporation rate depend on the thickness of the films and on the resin used:

Film of 30μ Film of 50μ Film of 100μ PE low density 2% 3% 5% PE high density 4% 5% 6% PP 5% 7% 10%

Technical Details & Test Data

- Note

- The melt flow (according to ISO 1133) can be adapted to user demand, according to the application

- Compounds & Masterbatches

For High Performance Plastic

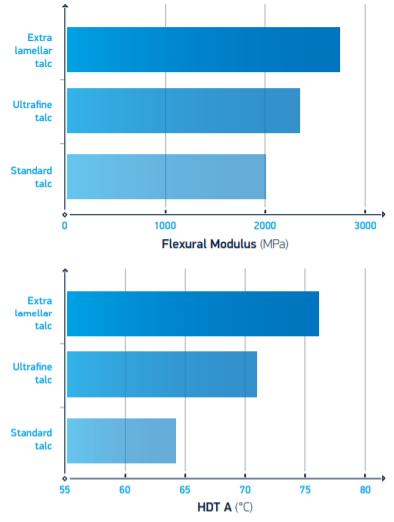

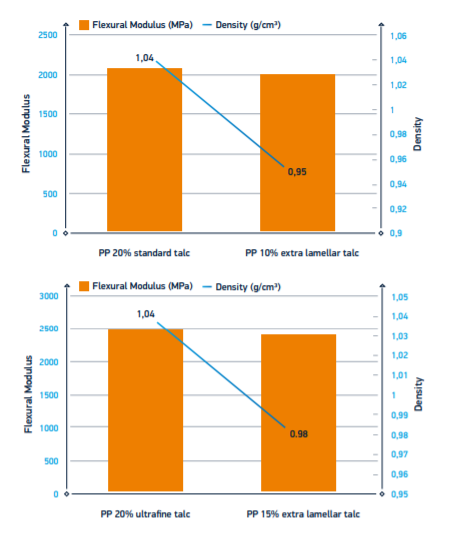

YOU WANT TO IMPROVE RIGIDITY AND HEAT DEFLECTION TEMPERATURE YOU WANT TO REDUCE WEIGHT ?

20% Talc PP compounds

Our innovative Extra lamellar Talc PP Compounds in comparison with standard and ultrafine talc.

For the use in compounding line or directly in injection molding.

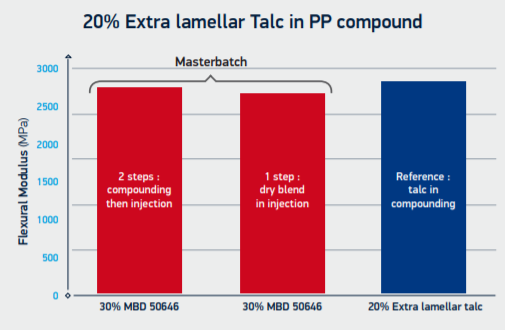

20% Extra lamellar Talc in PP compound

Good dispersion and talc lamellar morphology confirmed by flexural modulus consistency.

Packaging & Availability

- Packaging Type

- Packaging

- This masterbatch is packed in PE bag

Storage & Handling

- Storage

- This must be stored protected from light and from humidity.