Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Features

- High impact strength in all temperature zone

- High heat stability

- Good hydrolytic property

- Product Benefits

PVC

- Processability

- Mechanical Properties

- Dispersibility of Fillers

- Productivity

Engineering Plastics

- Mechanical Properties

- Flame retardancy

- Processability

Polyolefins Elastomers

- Processability

- Flame retardancy

- Dispersibility of Fillers

- Productivity improvement

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Applications

- Automotive & Transportation

- Electric & Electronic

- Aerospace & Aviation

- Consumer goods

Applicable Polymers & Resins

- PA, PBT, PET etc.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Particle Size | approx. 0.1 - 1 | μm |

Technical Details & Test Data

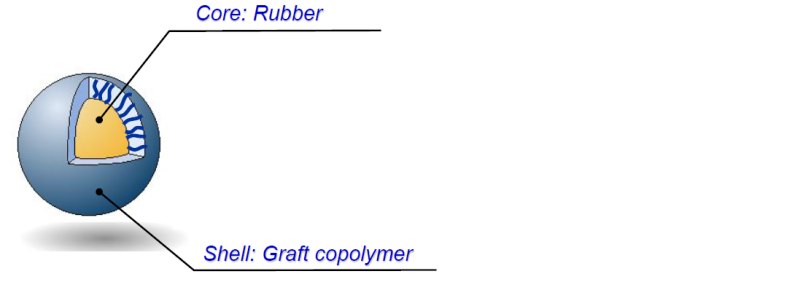

- METABLEN ’s Impact Modifier Technology

Particle size: 0.1~1μm

- METABLEN has various materials such as acrylic, silicone/acrylic, and butadiene.

- Shell (graft) gives rubber particles suitability to matrix resin.

- S 2200 is silicone acrylic rubber type impact modifier.

- S 2200 has epoxy group that control the suitability to matrix polymer.

Rubber type Rubber elasticity (at R.T.) Rubber elasticity

(at low temp.)Weatherability Acrylic ++ + ++ Silicone/Acrylic ++ ++ ++ Butadiene ++ ++ ー - Impact Modifier for PA

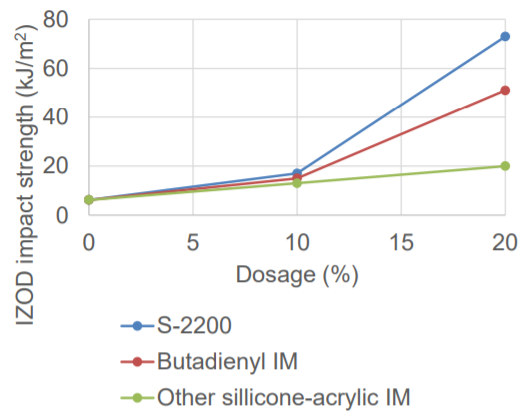

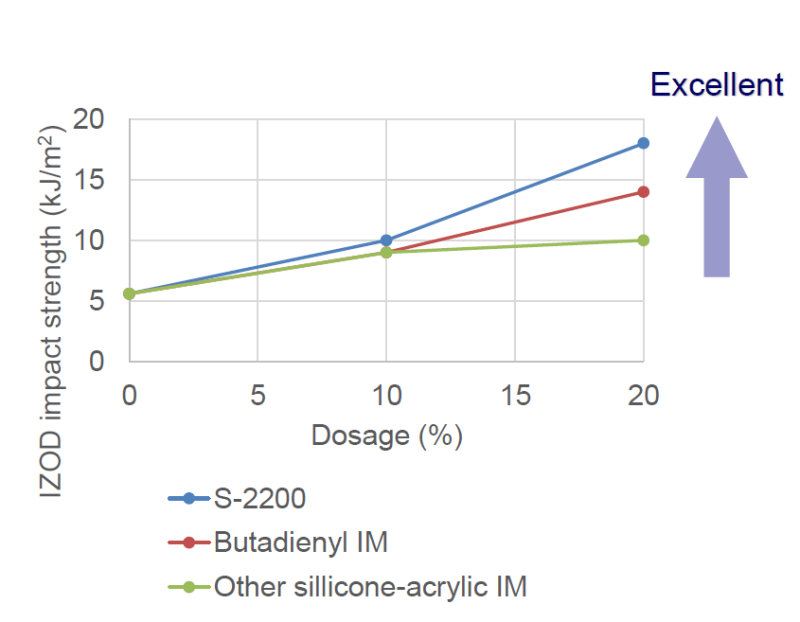

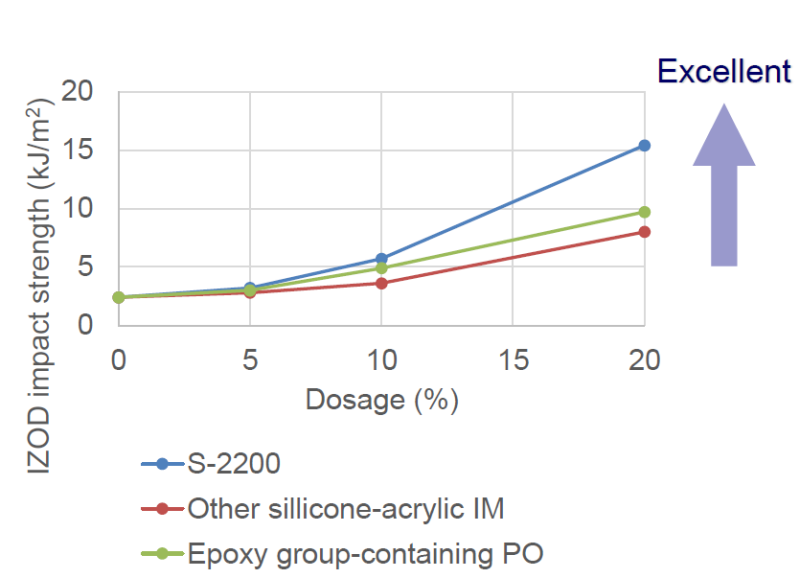

IZOD impact strength (23°C)

IZOD impact strength (40°C)

Test piece: 1/8 inch thickness, mold notched (set value)

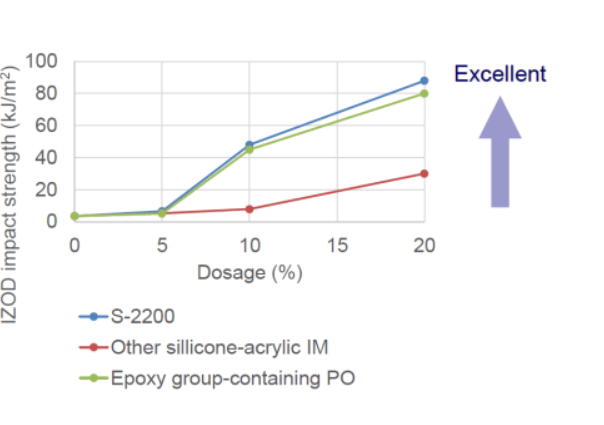

- Impact Modifier for PBT

IZOD impact strength (23°C)

IZOD impact strength (40 °C)

Test piece: 1/8 inch thickness, mold notched (set value)