Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Composition and Materials

Work Zone 100% Silicone Sealant is a 100% silicone polymer with no organic fillers.

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Basic Use

Recommended to seal nonporous surfaces around windows, doors, siding, gutters, vents, and more. Also use it for boats, cars, and more on windshields, fittings, and more. Great for use as an adhesive for fastening small accessories, fittings, repairing loose tiles, and more. Adheres to most nonporous surfaces, including clean metal, glass, most types of wood, silicone resin, vulcanized silicone rubber, ceramic, natural and synthetic fiber, painted surfaces, many plastic surfaces, and more.

- Limitations

Not recommended for continuous water immersion, or where abrasion and physical abuse are encountered. Do not apply to porous surfaces, such as masonry, or on building materials that bleed oils or solvents, such as certain impregnated woods and certain partially vulcanized rubber gaskets, tapes or adhesives. Do not use in totally confined spaces, because the sealant needs atmospheric moisture to cure. Do not use in aquariums as the bio agents in the sealant may be toxic in solution. Paint does not adhere well to silicone. Before product application, user should determine suitability of 100% silicone for intended use.

- Installation

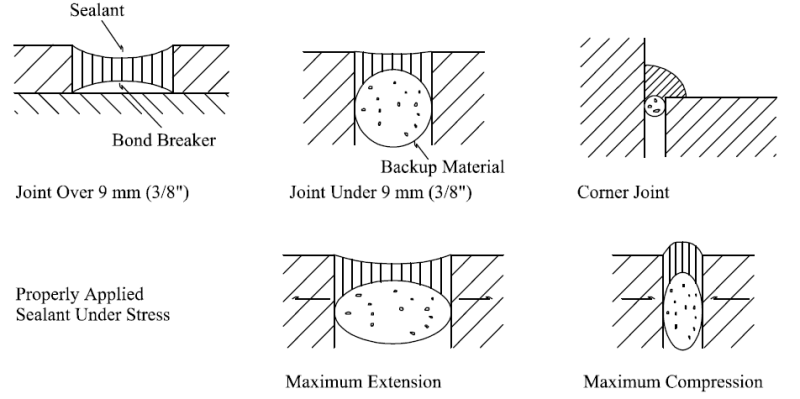

- Joints: Maximum joint size recommended is 13mm (½”).

- Surface Preparation: Thoroughly clean and degrease all surfaces. Then rinse all surfaces, except plastic, with acetone. Rubber surfaces should be roughened with sandpaper, then wiped with acetone.

- Joint Backing: Backer rods should be used in joints over 9mm (3/8”). Bond breaker tape should be used in shallower joints to prevent three sided adhesion.

- Weather Considerations: Do not apply to exterior surfaces if rain is expected within 24 hours.

- Service Time: Let dry 24 hours before exposing to water.

- Cleanup: There is no commercial solvent which will dilute uncured silicone, so care must be taken when applying. Wipe excess uncured silicone away carefully with a soft cloth.

- Recommended Methods of Application

Properties

- Odor

- Moderate Acetic Acid (Vinegar smell)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Brittle Point | -62.0 | °C | ASTM D 746 |

| BTU | 0.11 | /(ft) (°F) (hr) | - |

| Cure Time | 24.0 | hours | - |

| Cure Time (25°C, 50% RH, 1/8-inch thickness) | 24.0 | hours | - |

| Dielectric Constant (100 Hz) | 2.8 | - | - |

| Dielectric Constant (100 kHz) | 2.8 | - | - |

| Dielectric Constant (60 Hz) | 2.8 | - | - |

| Dielectric Strength | 550.0 | volts/mil | - |

| Dissipation Factor (100 Hz) | 0.0015 | - | - |

| Dissipation Factor (100 kHz) | 0.0015 | - | - |

| Dissipation Factor (60 Hz) | 0.0015 | - | - |

| Durometer Hardness | 27.0 | Shore A | ASTM D 2240 |

| Elongation | 600.0 | - | ASTM D 412 Die C |

| Extrusion Rate (1/8”orifice, 90psi) | 400.0 | g/min | - |

| Freeze - thaw Stability | Stable | - | - |

| Lap Shear Adhesion (1/16-inch lap joint thickness) | 192.0 | psi | - |

| Lap Shear Adhesion (1/2-inch lap joint thickness) | 37.0 | psi | - |

| Lap Shear Adhesion (1/4-inch lap joint thickness) | 67.0 | psi | - |

| Lap Shear Adhesion (1/8-inch lap joint thickness) | 113.0 | psi | - |

| Lap Shear Adhesion (3/8-inch lap joint thickness) | 44.0 | psi | - |

| Resistance to Dirt Pickup | Very Good | - | - |

| Skin Time (Under normal conditions) | 10 - 20 | minutes | - |

| Specific Gravity | 1.03 | - | - |

| Tack-free Time (25°C & 50% R.H.) | 1.0 | minute | - |

| Tensile Strength | 2.4 | MPa | ASTM D 412 Die C |

| Thermal Conductivity | 0.45x10⁻³ | cal / (cm) (°C) (sec) | - |

| Volume Coefficient of Thermal Expansion (0 to 100°C) | 9.3x10⁻⁴ | - | ASTM D 2137A |

| Volume Resistivity | 1.5x10¹⁵ | ohm-cm | - |

| Weathering (6,000 hours in Atlas Weatherometer) | No Change in Hardness | - | - |

| Weight | 1.03 | Kg/litre | - |

Regulatory & Compliance

- Applicable Standards

Work Zone 100% Silicone Sealant passes the performance requirements of the following specifications:

- CGSB CAN2-19.13-M87. Canadian standard for silicone sealants.

- TT-S-00230c (Class A), Type II. US federal spec for sealants.

- ASTM C 920 with the exception of glass adhesion through UV exposure.

- TT-S-1543A. US Federal specification for silicone sealing compounds.

- FDA Regulation No.21 CFR177.2600.

Packaging & Availability

- Packaging Type

- Availability

- Colors available: clear, white, bone, almond, brown, dark brown/bronze, gray, pewter, aluminum, black. Custom colors also available.

- Sizes: 300 ml cartridges, 18.9 liter pails, and 200 liter drums.

- Grade: gun grade, nonsagging.

- Availability and Cost

Marketed throughout Canada and some foreign countries. Work Zone 100% Silicone Sealant is sold through building supply, hardware, paint, and specialty distributors. Costs are available from local Work Zone distributors and representatives, or from company corporate offices.

Storage & Handling

- Shelf Life

- min. 2 Years

- Storage Temperature

Unaffected by temperature, but +5°C to 37°C (40°F to 100°F) is recommended.