Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Product Highlights

- Toughened epoxy matrix with excellent mechanical properties

- Elevated temperature performance

- Good translation of fiber properties

- Controlled matrix flow in processing

- Available on various reinforcements

- Excellent drape and tack

Applications & Uses

Properties

- Physical Form

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| In-Plane Shear Strength (93°C, Dry) | 106 | MPa | - |

| In-Plane Shear Strength (25°C, Dry) | 120 | MPa | - |

| ILSS (Shortbeam shear At 71°C, Wet) | 80 | MPa | - |

| ILSS (Shortbeam shear at 25°C, Wet) | 115 | MPa | - |

| ILSS (Shortbeam shear at 91°C, Dry) | 94 | MPa | - |

| ILSS (Shortbeam shear at 25°C, Dry) | 137 | MPa | - |

| Compression Modulus (91°C, Dry) | 162 | GPa | - |

| Compression Modulus (25°C, Dry) | 150 | GPa | - |

| Compression Strength (91°C, Dry) | 1483 | MPa | - |

| Compression Strength (25°C, Dry) | 1690 | MPa | - |

| Tensile Modulus (91°C, Dry) | 10 | GPa | - |

| Tensile Modulus (91°C, Dry) | 163 | GPa | - |

| Tensile Modulus (25°C, Dry) | 12 | GPa | - |

| Tensile Modulus (25°C, Dry) | 164 | GPa | - |

| Tensile Modulus (55°C, Dry) | 163 | GPa | - |

| Tensile Strength (91°C, Dry) | 92 | MPa | - |

| Tensile Strength (91°C, Dry) | 2538 | MPa | - |

| Tensile Strength (25°C, Dry) | 64 | MPa | - |

| Tensile Strength (25°C, Dry) | 2724 | MPa | - |

| Tensile Strength (-55°C, Dry) | 174 | MPa | - |

| Tensile Strength (-55°C, Dry) | 2572 | MPa | - |

| Value | Units | Test Method / Conditions | |

| Nominal Laminate Density (IM7) | 1.57 | g/cm³ | - |

| Nominal Fibre Volume (IM7) | 57.7 | % | - |

| Nominal Cured Ply Thickness (8552 /35%/134, IM7) | 0.131 | mm | - |

| Resin Density (IM7) | 1.3 | g/cm³ | - |

| Filiament Count/Tow (IM7) | 12K | - | - |

| Fibre Density (IM7) | 1.77 | g/cm³ | - |

| Resin Density | 1.30 (0.047) | g/cm³ (lb/in³) | - |

| Nominal Laminate Density | 1.57 (0.057) | g/cm³ (lb/in³) | - |

| Fibre Density | 1.77 (0.064) | g/cm³ (lb/in³) | - |

Technical Details & Test Data

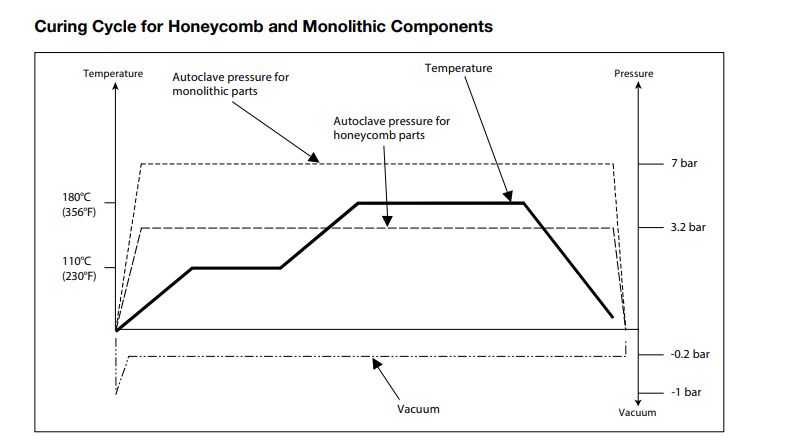

- Curing Conditions

Cure cycle for monolithic components1. Apply full vacuum (1 bar).

2. Apply 7 bar gage autoclave pressure.

3. Reduce the vacuum to a safety value of 0.2 bar when the autoclave pressure reaches approximately 1 bar gage.

4. Heat at 1- 3°C/min (2-8°F/min) to 110°C ± 5°C (230°F ± 9°F)

5. Hold at 110°C ± 5°C (230°F ± 9°F) for 60 minutes ± 5 minutes.

6. Heat at 1-3°C/min (2-8°F/min) to 180°C ± 5°C (356°F ± 9°F)

7. Hold at 180°C ± 5°C (356°F ± 9°F) for 120 minutes ± 5 minutes.

8. Cool at 2 - 5°C (4-9°F) per minute

9. Vent autoclave pressure when the component reaches 60°C (140°F) or below.Cure cycle for honeycomb sandwich components

1. Apply full vacuum (1 bar).

2. Apply 3.2 bar gage autoclave pressure.

3. Reduce the vacuum to a safety value of 0.2 bar when the autoclave pressure reaches approximately 1 bar gage.

4. Heat at 1- 3°C/min (2-8°F/min) to 110°C ± 5°C (230°F ± 9°F)

5. Hold at 110°C ± 5°C (230°F ± 9°F) for 60 minutes ± 5 minutes.

6. Heat at 1-3°C/min (2-8°F/min) to 180°C ± 5°C (356°F ± 9°F)

7. Hold at 180°C ± 5°C (356°F ± 9°F) for 120 minutes ± 5 minutes.

8. Cool at 2 - 5°C (4-9°F) per minute

9. Vent autoclave pressure when the component reaches 60°C (140°F) or below.

Storage & Handling

- Storage Life

- Tack Life: 10 days at RT (23°C/73°F)

- Out Life: 30 days at RT (23°C/73°F)

- Shelf Life: 12 months at -18°C(0°F) (maximum, from date of manufacture)