Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Pharma & Nutraceuticals Functions

- Molecular formula

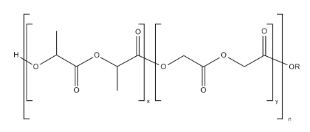

- -[(C₆H₈O₄)x(C₄H₄O₄)ᵧ]ₙ-

- Technologies

- Chemical Structure

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Animal Species

Properties

- Typical Properties

- Specifications

| Value | Units | Test Method / Conditions | |

| Inherent Viscosity (Measured in HFIP) | 0.55 - 0.75 | dL/g | - |

| Value | Units | Test Method / Conditions | |

| Polymer Composition (DL-Lactide) | 45 - 55 | mole % | - |

| Polymer Composition (Glycolide) | 45 - 55 | mole % | - |

| Residual Monomer | max. 2.0 | mole % | - |

| Residual Tin | max. 200 | ppm | - |

| Residual Toluene | max. 890 | ppm | - |

| Solubility (5 wt% in acetone) | Soluble | - | - |

| Residue on Ignition | max. 0.1 | % | - |

| Total Aerobic Microbial Count | max. | CFU/g | - |

| Total Yeast and Molds Count | max. 10² | CFU/g | - |

| Bacterial Endotoxins | max. 0.5 | EU/g | - |

| Glass Transition Temp | 45 - 50 | °C | - |

| Approx. Resorption | 1 - 2 | months | - |

| Density | 1.34 | g/mL | - |

| Tensile Strength | 6000 - 8000 | psi | - |

| Elongation | 3 - 10 | % | - |

| Modulus | 2 - 4x10⁵ | psi | - |

| Crystalline Melt Transition | Amorphous | °C | - |

Regulatory & Compliance

- Certifications & Compliance

- Grade

Packaging & Availability

- Packaging Type

- Packaging Information

Biodegradable polymers must be packaged to strict requirements in order to be protected from degradation by moisture. At Evonik, we package our polymers in heat-sealed polyethylene bags under high-purity nitrogen. These polyethylene bags along with a desiccant pouch are heat-sealed into foil-laminate outer bags. All packaging is performed in a clean room. We also offer special packaging, such as multiple containers or alternative sizes, to support your production and R&D needs.

Storage & Handling

- Shelf Life

- max. 3 months

- Storage Conditions

The packaged polymers are labeled for storage at ≤ -10 °C.