Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Pharma & Nutraceuticals Functions

- CAS No.

- 25086-89-9

- EC No.

- 607-540-1

- Technologies

Features & Benefits

- Features

Physical Properties:

Non-ionic polymer

Low hygroscopic

Good plastic deformation

Good fluidity and compressibility

Low glass transition temperaturePerformance Impact:

No interaction with ionic APIs

The vinyl acetate component in Stardone®VA64 reduces the hydrophilicity

The vinyl acetate component has greatly improved the plasticity of Stardone®VA64, making it exceptionally well as a binder for direct compression

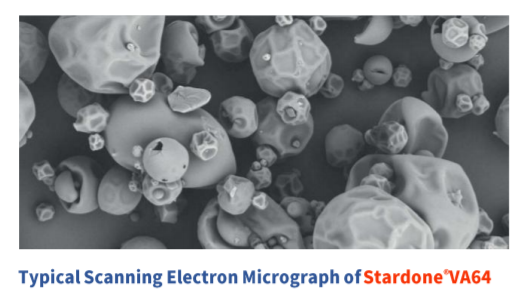

Hollow particle morphology provides good fluidity of Stardone®VA64, and large surface area enhances the bonding and compressibility of particles

Ideal glass transition temperature(Tg) for hot melt extrusion- Direct Compression : Excellent binder at 2-10% with other direct compression binder-fillers such as MCC, dicalcium phosphate, etc.

- Dry Granulation :Can be used as a binder in dry granulation(roller compaction).

- Wet Granulation:Enables wet granulation of moisture sensitive due to low hygroscopicity.

- Hot Melt Extrusion: Acts as a polymer matrix for solid dispersions/solutions via hot melt extrusion due idea glass transition temperature at 105℃

- Film Coating: Ideally suited as co-film-former

- Summary

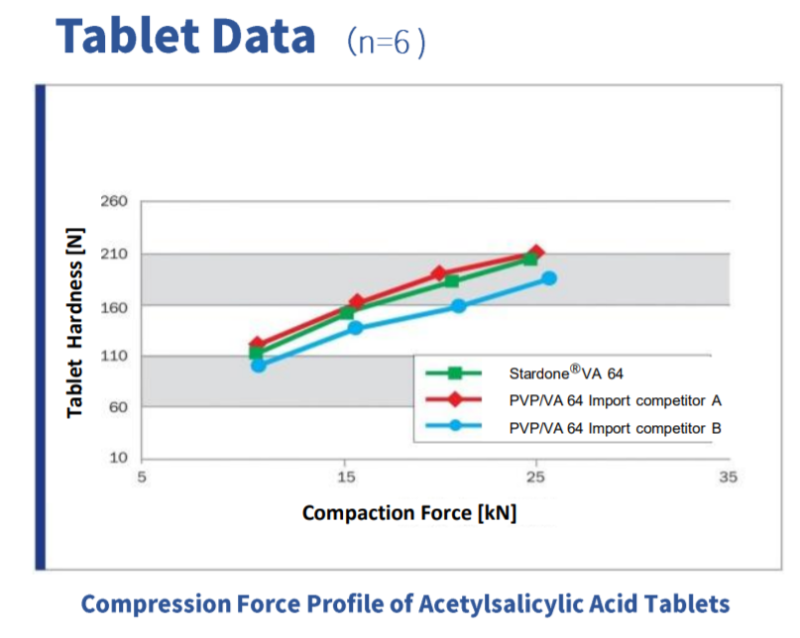

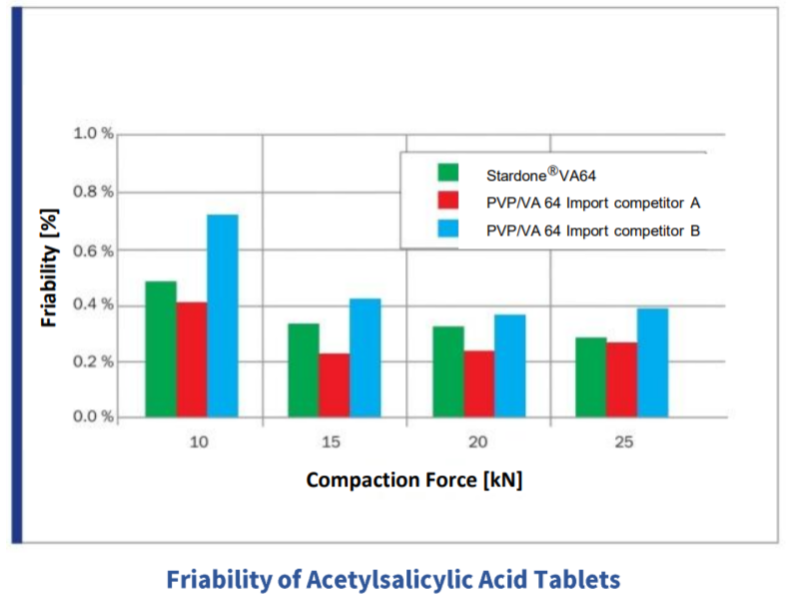

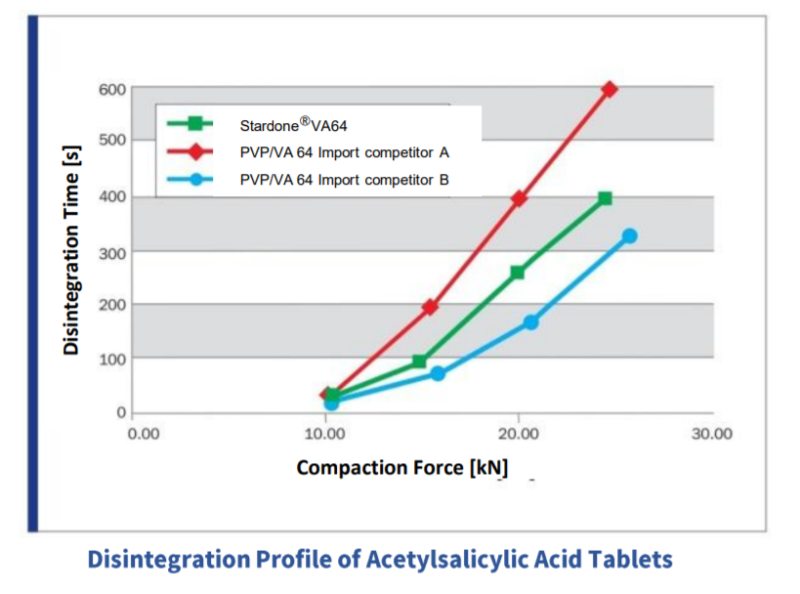

A direct compression formulation of acetylsalicylic acid was achieved with Stardone®VA64. Although acetylsalicylic acid is known to be poorly compressible, the formulation resulted in robust tablets with low friability at all compaction forces, as well as good disintegration times. Stardone®VA64 has similar performance to import competitor A and import B in terms of tablet hardness, friability, and disintegration time.

Applications & Uses

- Markets

- Manufacturing Technology

Properties

Regulatory & Compliance

- Certifications & Compliance

- Grade

Technical Details & Test Data

- Technical Analysis

- Case Study

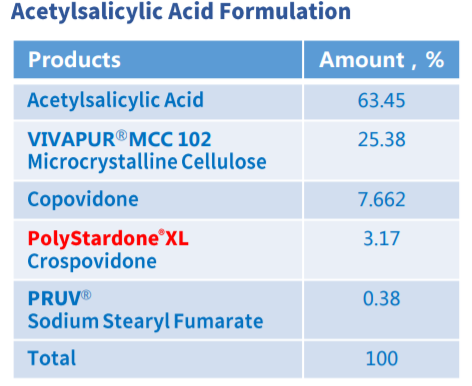

A direct compression formulation of acetylsalicylic acid, a poorly compressible API, was selected to compare the functionality of Stardone®VA64 against other PVP/VA 64 products on the market.

- Tablet Data (n=6)

Packaging & Availability