Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Industrial Additives Functions

- Technologies

Features & Benefits

- Industrial Additives Features

- Features

- Produced in the United States from a pulverized blend of high quality, domestically mined bituminous coals resulting in a consistent, high quality product.

- Carbon granules are uniformly activated through the whole granule, not just the outside, resulting in excellent adsorption properties and constant adsorption kinetics.

- The reagglomerated structure ensures proper wetting while also eliminating floating material.

- High mechanical strength relative to other raw materials, thereby reducing the generation of fines during backwashing and hydraulic transport.

- Carbon bed segregation is retained after repeated backwashing, ensuring the adsorption profile remains unchanged and therefore maximizing the bed life.

- Reagglomerated with a high abrasion resistance, which provides excellent reactivation performance.

- High density carbon resulting in a greater adsorption capacity per unit volume.

- Recycling and Reactivation

Though FILTRASORB is 100-percent freshly manufactured virgin GAC, it can be recycled and reused through thermal reactivation to restore its adsorptive capacity. This eliminates the costs and long-term liability associated with the disposal of spent GAC, and provides customers with a consistent, reliable supply of filtration media.

Applications & Uses

- Markets

- Applicable Processes

- Industrial Additives End Use

- Applications

- Industrial Wastewater

- Groundwater

- Surface Water

- Pond/Aquarium/ Swim

- Bottle & Brewing

- Water Processing

- Pharmaceuticals

- Environmental Water

- Food & Beverage

- Drinking Water Industrial

- Water Reuse

- Drinking Water (Potable)

- Granular Activated Carbon

- Municipal

- Reactivation

FILTRASORB 200 activated carbon can be used in a variety of liquid phase applications for the removal of dissolved organic compounds. FILTRASORB 200 has been successfully applied for over 40 years in applications such as drinking and process water purification, wastewater treatment, and food, pharmaceutical, and industrial purification.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Apparent Density (Tamped) | 0.58 | g/cc | - |

| Effective Size | 0.55 - 0.75 | mm | - |

| Non-Wettable | max. 1 | % | - |

| Water Extractables | max. 1 | % | - |

| Uniformity Coefficient | max. 1.9 | - | - |

| Moisture Content (by Weight) | max. 2 | % | - |

| Screen Size (by Weight, US Sieve Series Through 30 mesh) | max. 4 | % | - |

| Screen Size (by Weight, US Sieve Series on 8 mesh) | max. 5 | % | - |

| Abrasion Number | min. 75 | - | - |

| Iodine Number | min. 850 | mg/g | - |

Regulatory & Compliance

- Regulatory

FILTRASORB 200 is formulated to comply with all the applicable provisions of the AWWA Standard for Granular Activated Carbon (B604) and Food Chemicals Codex. This product may also be certified to the requirements of NSF/ANSI 61 for use in municipal water treatment facilities. Only products bearing the NSF Mark are certified to the NSF/ANSI 61 - Drinking Water System Components - Health Effects standard. Certified Products will bear the NSF Mark on packaging or documentation shipped with the product.

Technical Details & Test Data

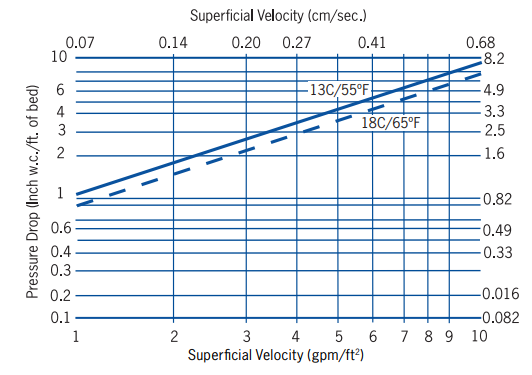

- Typical Pressure Drop

Based on a backwashed and segregated bed

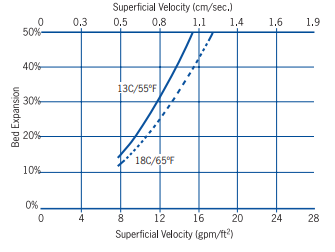

- Typical Bed Expansion During Backwash

Based on a backwashed and segregated bed

- Process

This activated carbon is made from select grades of bituminous coal through a process known as reagglomeration to produce a high activity, durable, granular product capable of withstanding the abrasion associated with repeated backwashing, hydraulic transport, and reactivation for reuse. The raw coal is mined and subsequently manufactured into GAC in the United States to ensure the highest quality and consistency in the finished product. Activation is carefully controlled to produce a significant volume of both low and high energy pores for effective adsorption of a broad range of high and low molecular weight organic contaminants.

- Conditioning and Backwashing

Backwashing and conditioning fresh GAC before placing into operation is critical to GAC performance. The reasons for backwashing before placing fresh media online are to: (1) size segregate the media so subsequent backwashing will return the media to the same relative position in the bed, (2) remove any remaining air from the bed, and (3) remove media fines which can lead to excessive pressure drop and flow restriction. In addition, proper backwashing is a crucial step to collecting the most representative and meaningful post-start up data on compounds of interest, such as metals listed in the NSF/ANSI 61 standard.

Below are the recommended steps for proper conditioning and backwashing of GAC based on Filtrasorb 200 GAC being backwashed at 55°F:

- Fully submerge GAC bed in clean, contaminant free water for at least 16 hours (overnight)

- Open backwash inlet and begin up-flow at 6 gpm/ft2 for 2 minutes

- Increase flow to 8 gpm/ft2 and maintain for 2 minutes

- Increase flow to 10 gpm/ft2 and maintain for 2 minutes

- Increase flow to 12 gpm/ft2 and maintain for 30 minutes (Duration representative of initial backwash conditions. Required duration during operational backwashes can be shorter but will vary by utility, solids load, and GAC throughput.)

- Decrease flow to 10 gpm/ft2 and maintain for 2 minutes.

- Decrease flow to 8 gpm/ft2 and maintain for 2 minutes.

- Decrease flow to 6 gpm/ft2 and maintain for 2 minutes.

- Close backwash inlet and stop flow.

- Design Considerations

FILTRASORB 200 activated carbon is typically applied in down-flow packed-bed operations using either pressure or gravity systems. Design considerations for a treatment system is based on the user’s operating conditions, the treatment objectives desired, and the chemical nature of the compound(s) being adsorbed.

Safety & Health

- Safety

Wet activated carbon can deplete oxygen from air in enclosed spaces. If use in an enclosed space is required, procedures for work in an oxygen deficient environment should be followed.